Walnut Slab Counter

ROLE: SKETCH IDEATION, 3D Modeling, WOODWORKING, FINISHING

Role: Sketch IDEATION, 3D CAD, WOODWorking, FINISHING

walnut Slab COunter

This kitchen counter was made from a locally-sourced slab of live edge walnut from Horigan Urban Forestry Products. Not having space for a full dining table, we opted for a slim countertop that could serve as place for a quick meal, some coffee/tea, or cocktails.

Design

Having a affection towards the live edge furniture by George Nakashima, I wanted to discover and learn about the process involved with flattening, debarking, stabilizing cracks and filling knots, and finishing a slab of wood into a food-friendly counter top.

We measured out kitchen space and went searching for a slab at the Horigan Urban Forestry Products warehouse in the northern suburbs of Chicago and decided on a beautiful piece of black walnut.

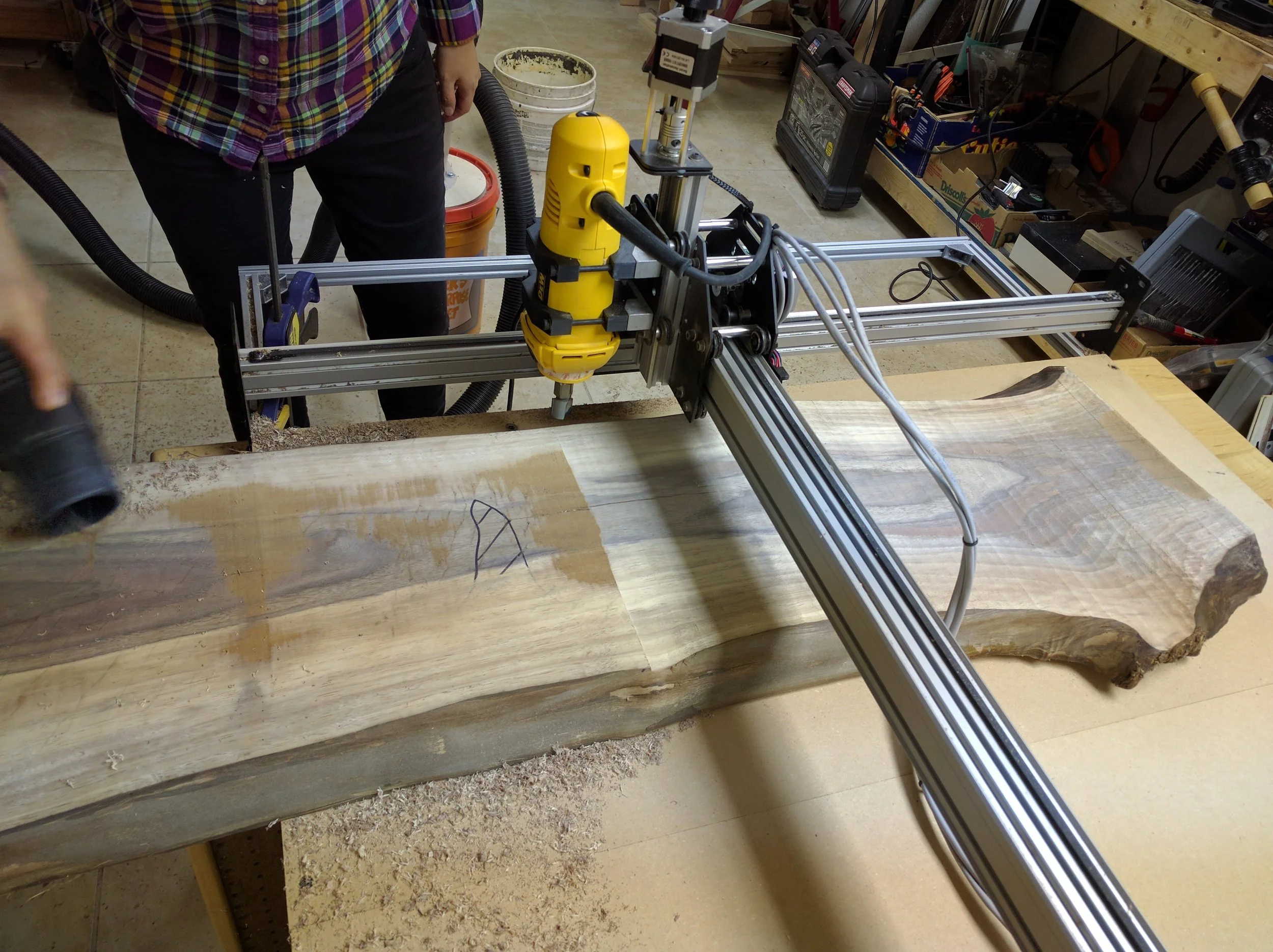

It was a quite a challenge trying to flatten the board without a planer wide enough to accommodate the thickness of the board. After hours of planing with a Stanley #5 jack plane, I decided I needed a better strategy. I used a Shapeoko CNC machine fitted with a large routing bit, which functioned as a large router sled to face the slab a la Nick Offerman.

I followed with some more hand planing with a Stanley #5 jack plane and then a #4 smoothing plane. Cracks were filled with epoxy and cleaned up with a chisel and scraper and then I coated the top with several coats of a wipe-on low gloss poly finish, followed by a food-safe beeswax. I opted for a black pipe base due to cost and availability with some L brackets to secure it to the wall.